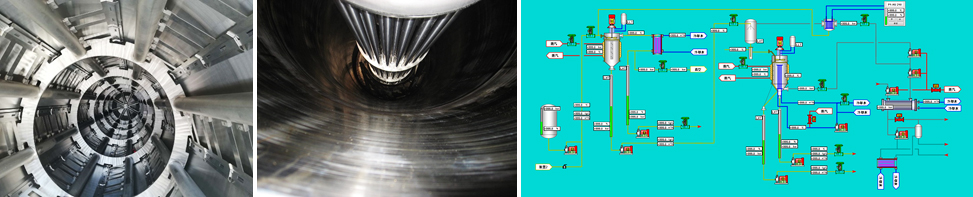

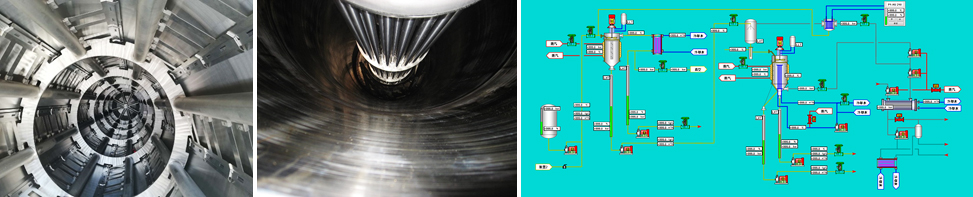

1. Scraper molecular distillation

Equipment Introduction

Equipment Introduction

Molecular distillation is a special liquid-liquid separation technology, which is different from the traditional distillation principle of relying on differences between the boiling point. The equipment separates the components by the difference of the average free path of the molecular motion of different substances. There are four main types of molecular distillation: falling film, wiped film, centrifugal and scraper molecular distillation. Among them, scraper distillation equipment is more popular than other forms.

Equipment features

1. Low operating temperature and stable performance of materials.

2. It is safe with low pressure during the evaporation.

3. The short heating time and high efficiency.

4. High separation degree, especially for the purification and separation of high boiling point and heat sensitive materials.

5. Our team has rich experience both in installation and commissioning on the site. In addition, our company has perfect service system after sale.

Application

Application

Molecular distillation equipment used in lactic acid

Wiped-Film Molecular Still is widely used in the fields of pharmaceuticals, food, fermentation, metallurgy, printing and dyeing, inorganic salts, chemical industry, etc.

Wiped-Film Molecular Still is widely used in the fields of pharmaceuticals, food, fermentation, metallurgy, printing and dyeing, inorganic salts, chemical industry, etc.

-Sugar industry

starch sugar, including glucose, dextrose monohydrate, fructose, crystalline fructose, F42, F55, maltose, dextrin, etc.; xylose.

-Chemical industry

Organic acids include L-lactic acid, citric acid, VC, monosodium glutamate, and various amino acids, such as lysine, L-phenylalanine, leucine, methionine, etc.

-Food industry

Stevia sugar, sorbitol, and xylitol and sodium erythorbate, etc.

-Pharmaceutical industry

antibiotics, etc.

-Thermoelectric industry

water treatment, etc.

-Biology fermentation industry

L- lactic acid, etc.