1. Automatic simulated moving bed chromatographic separation equipment

Equipment principle

Equipment principle

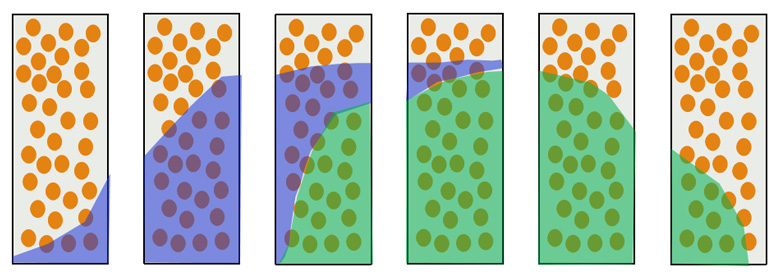

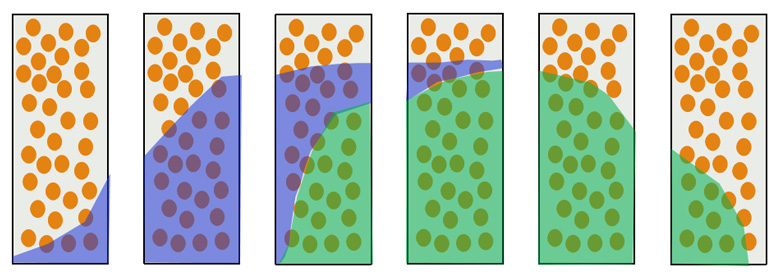

Chromatographic separation is carried out in a chromatographic column equipped with a "stationary phase". The stationary phase must have sufficient retention difference for the separated components so that the difference in flow rate of the separated components can be used to achieve two-component separation or the multi-component separation. Automatic simulated moving bed chromatographic separation equipment can effectively separate two or more components.

Schematic diagram of automatic simulated moving bed chromatographic separation

Equipment features

Equipment features

1. Intermittent operation.

2.The number of columns is 4-6, the one-time investment is reduced, but the separation effect is comparable to traditional chromatographic separation.

3. The equipment greatly improves product purity, and by-products with a high purity are utilized. What’s more, the total cost is reduced.

4. Fully automated operation reduces human factors. The sugar content(Brix), pressure, liquid level can be monitored online. So the operation is safer and more reliable.

5. The used valve from European brands is reliable and the system is pretty safe.

6. Our team has rich experience both in installation and commissioning on the site. In addition, our company has perfect service system after sale.

Application

Application

Automatic simulated moving bed chromatographic separation Equipment used in dextrose monohydrate and polysaccharide

Automatic simulated moving bed chromatographic separation Equipment is widely used in the fields as follows.

Automatic simulated moving bed chromatographic separation Equipment is widely used in the fields as follows.

-Sugar industry

starch sugar, including crystalline glucose, fructose, crystalline fructose, F42, F55, maltose, dextrin, etc.; xylose.

-Chemical industry

Organic acids include L-lactic acid, citric acid, VC, monosodium glutamate, and various amino acids, such as lysine, L-phenylalanine, leucine, methionine, etc.

-Food industry

Stevia sugar, sorbitol, and xylitol and sodium erythorbate, etc.

-Pharmaceutical industry

antibiotics, etc.