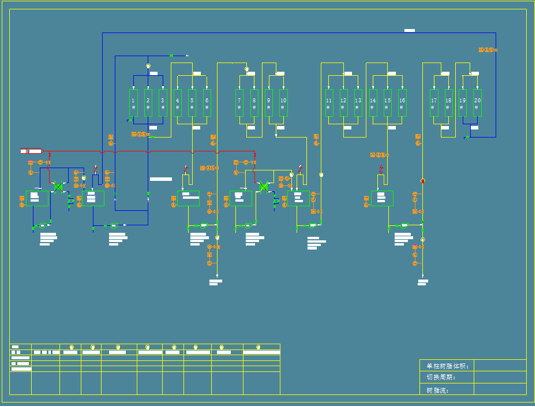

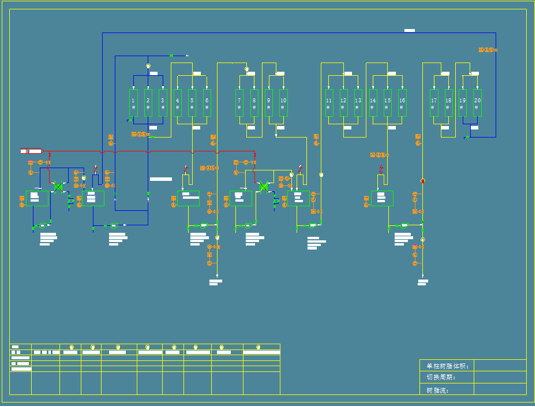

2. Multi-unit continuous chromatographic separation equipment with array valves

Equipment principle

Equipment principle

The multi-unit continuous chromatographic separation equipment with array valves divides resin into multiple units and use many valves to utilize the resin achieving precisely the purpose of product separation.

Equipment features

Equipment features

1. Multi-unit continuous chromatographic separation equipment can be truly continuous operation without pump shutdown. The complete large cycle starts together with feeding, watering and discharging, which improves the operating efficiency of the system. The consumption of resin will generally diminish by 20%-30% at least.

2. The longer distance for the separation process is beneficial to improve the separation effect and obtain high-purity components.

3. It would save energy later that the equipment runs in series to elute products.

4. Multi-unit continuous chromatographic separation equipment runs continuously without shutdown or starting, which makes it much safer.

5. The equipment greatly improves product purity, and high-purity by-products are utilized. What’s more, the total cost is reduced.

6. Fully automated operation reduces human factors. The sugar content(Brix), pressure, liquid level can be monitored online so the operation is safer and more reliable.

7. The used valve from European brands is reliable and the system is pretty safe.

8. Our team has rich experience both in installation and commissioning on the site. In addition, our company has perfect service system after sale.

Application

Application

Multi-unit continuous chromatographic separation equipment with array valves used in fructose and glucose

Multi-unit continuous chromatographic separation equipment with array valves is widely used in the fields as follows.

Multi-unit continuous chromatographic separation equipment with array valves is widely used in the fields as follows.

-Sugar industry

starch sugar, including crystalline glucose, fructose, crystalline fructose, F42, F55, maltose, dextrin, etc.; xylose.

-Chemical industry

organic acids include L-lactic acid, citric acid, VC, monosodium glutamate, and various amino acids, such as lysine, L-phenylalanine, leucine, methionine, etc.

-Food industry

Stevia sugar, sorbitol, and xylitol and sodium erythorbate, etc.

-Pharmaceutical industry

antibiotics, etc.