3. MVR evaporator

Equipment Introduction

Equipment Introduction

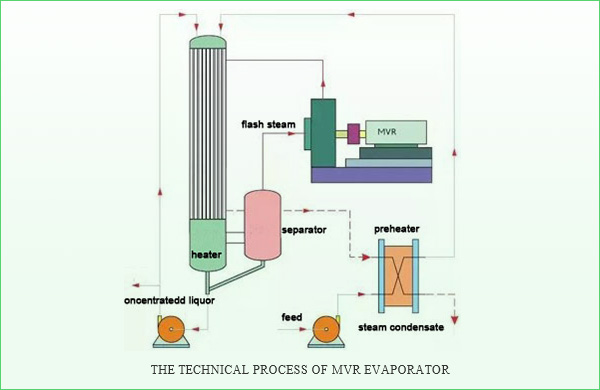

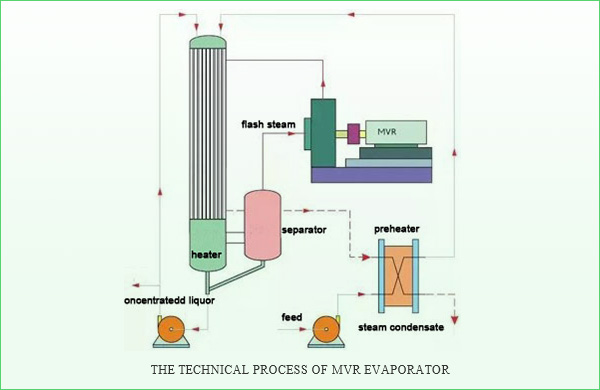

The MVR evaporator is a new type of high-efficiency energy-saving evaporation equipment mainly used in the pharmaceutical industry. The equipment uses the clean energy with the steaming technology of low-temperature and low-pressure to evaporate. It separates the water from feed liquid. In brief, it is an advanced technology in the domestic and overseas and MVR evaporator is a piece of upgraded equipment that can replace the traditional evaporator.

Equipment principle

Equipment principle

MVR evaporator is different from common single-effect falling film or multi-effect falling film evaporators. MVR is a new single-effect evaporator, which is equal to integrating multi-effect falling film evaporator. It adopts stage evaporation according to the required product concentration. When the desired concentration cannot be reached after the first evaporation, the product is pumped through the external pipe of the evaporator to the upper inlet again by the vacuum pump. And then the feed liquid passes through the evaporation body again to achieve the desired concentration.

Equipment features

Equipment features

1. It is none of fresh steam so it saves energy.

2. The process is simple but is practical.

3. It runs stably together with high automation.

4. Short residence time and high efficiency.

5. Due to the low temperature difference, the evaporation process of the product is mild and the product quality is good.

6. Low operating cost, it can evaporate below 40 ℃ without freezing equipment, especially it is suitable for heat-sensitive materials.

7. Our team has rich experience both in installation and commissioning on the site. In addition, our company has perfect service system after sale.

Application

Application

MVR evaporator used in starch sugar

MVR evaporator is widely used in the fields of pharmaceuticals, food, fermentation, metallurgy, printing and dyeing, inorganic salts, chemical industry, etc.

MVR evaporator is widely used in the fields of pharmaceuticals, food, fermentation, metallurgy, printing and dyeing, inorganic salts, chemical industry, etc.

-Sugar industry

starch sugar, including glucose, dextrose monohydrate, fructose, crystalline fructose, F42, F55, maltose, dextrin, etc.; xylose.

-Chemical industry

Organic acids include L-lactic acid, citric acid, VC, monosodium glutamate, and various amino acids, such as lysine, L-phenylalanine, leucine, methionine, etc.

-Food industry

Stevia sugar, sorbitol, and xylitol and sodium erythorbate, etc.

-Pharmaceutical industry

antibiotics, etc.

-Biology fermentation industry

L- lactic acid, etc.

-Environmental protection industry�����,

wastewater treatment, etc.