4. Multiple-hearth kiln

Equipment principle

Equipment principle

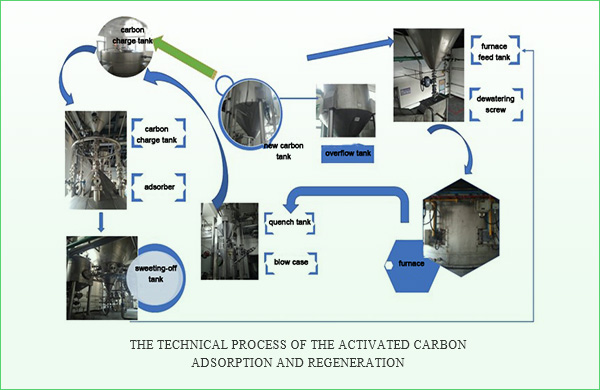

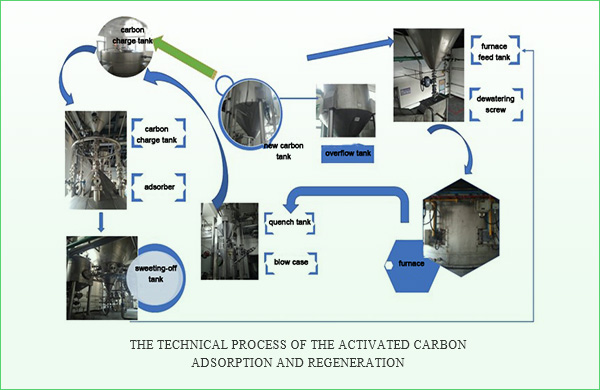

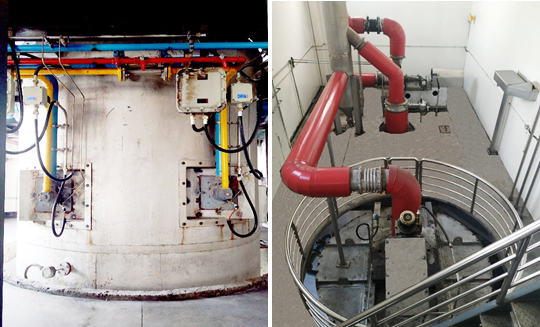

Multiple hearth furnace is best used to match the adsorption equipment. After adsorption process, the spent carbon that is granular is pumped to multiple hearth furnace for regeneration many times.

Equipment features

Equipment features

1. The activated carbon is regenerated in the furnace, which is useful for environment and resource.

2. Accurate control of gas volume and activation process to keep feed and discharge continuous, and ensure products are of satisfactory quality.

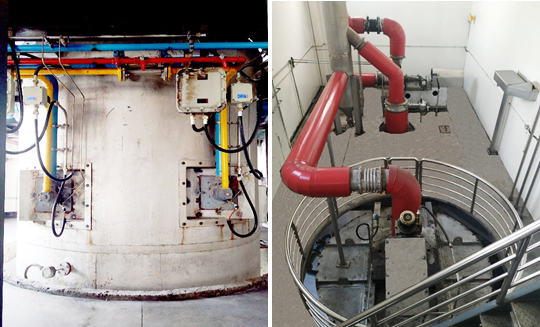

3. The regenerative furnace body has a solid structure and can be used continuously for many years.

4. The regenerative furnace can realize fully automatic control. And it is high efficiency and safety.

5. High degree of automation is conducive to the construction and transformation of intelligent workshops.

6. Equipment maintenance is simple and economical, and the average operating cost is low.

7. Our team has rich experience both in installation and commissioning on the site. In addition, our company has perfect service system after sale.

Application

Application

Multiple hearth kiln used in glucose

Multiple hearth kiln is widely used in the fields as follows.

Multiple hearth kiln is widely used in the fields as follows.

1. Adsorption and Regeneration of Granular Activated Carbon, including the following fields,

-Sugar industry

starch sugar, including glucose, dextrose monohydrate, fructose, crystalline fructose, F42, F55, maltose, dextrin, etc.; xylose.

-Chemical industry

Organic acids include L-lactic acid, citric acid, VC, monosodium glutamate, and various amino acids, such as lysine, L-phenylalanine, leucine, methionine, etc.

-Food industry

Stevia sugar, sorbitol, and xylitol and sodium erythorbate, etc.

Pharmaceutical industry

antibiotics, etc.

-Thermoelectric industry

water treatment, etc.

2. The treatment for incineration tail gas, and the application for heat energy recovery project.

3. Calcination of kaolin.

4. Calcination of non-ferrous metals (such as molybdenum, nickel, copper, zinc, etc.).

5. The combustion treatment of industrial hazardous materials (solid, liquid, gas), such as the sludge of sewage treatment plants.