1. Multi-unit continuous ion exchange equipment with array valves

Equipment principle

Equipment principle

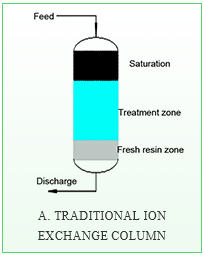

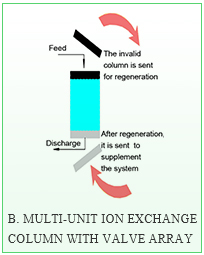

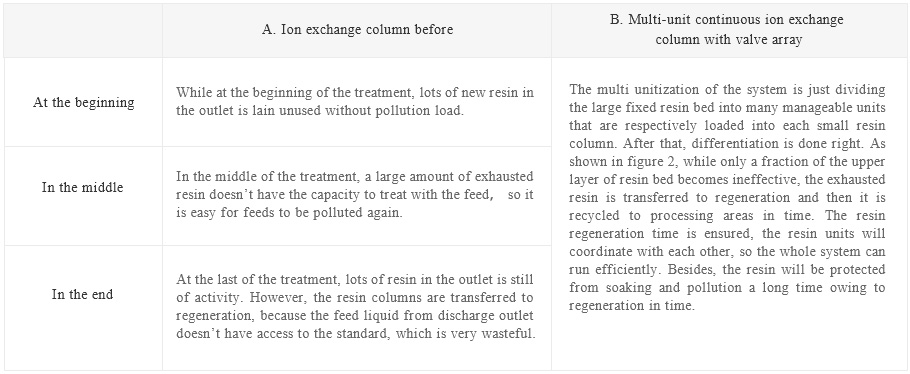

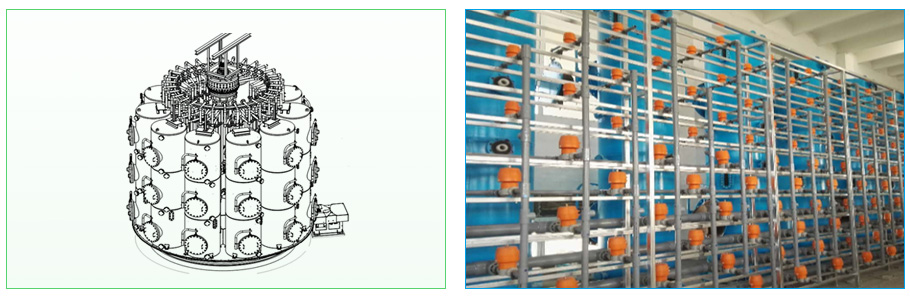

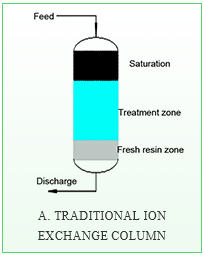

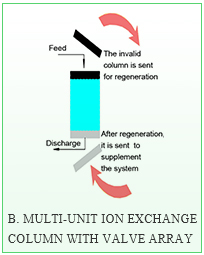

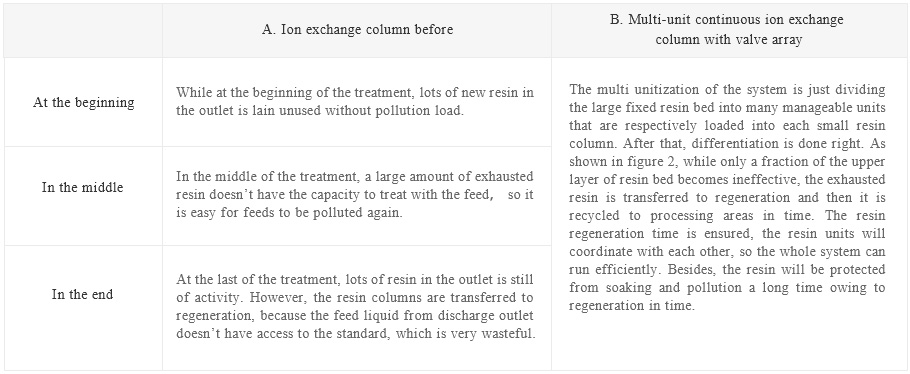

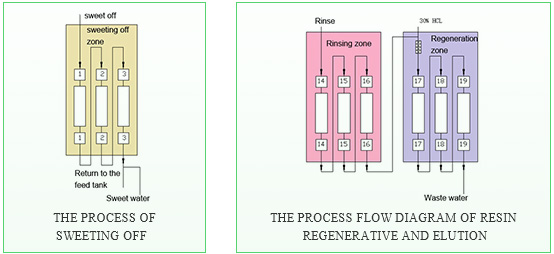

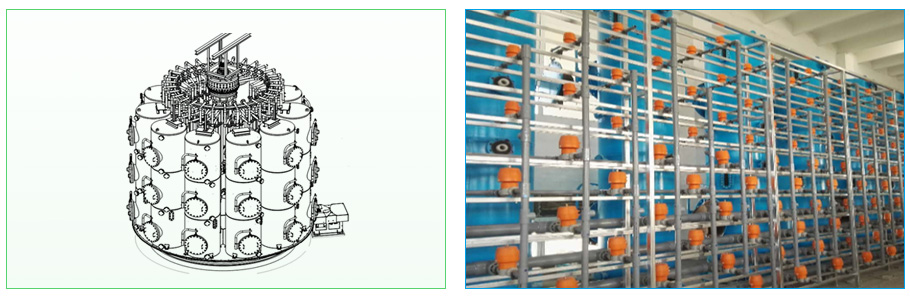

It is the same with a common ion exchange system. The resin in our equipment is filled in the column and it is regenerated after use. More importantly, the resin in the entire system is divided into more units for more detailed operation. The multi unitization of the system is just dividing the large fixed resin bed into many manageable units that are respectively loaded into each small resin column.

Array valves

Many valves and some pipelines are linked together to become a part of the ion exchange system, which is called valve array. We can switch a certain valve to realize the corresponding functions.

Multi-unit

The resin in the entire system is divided into more units for more detailed operation.

Equipment advantages

Equipment advantages

1. Reducing the amount of resin to increase the resin utilization rate

2. Series operation to reduce consumption and sewage

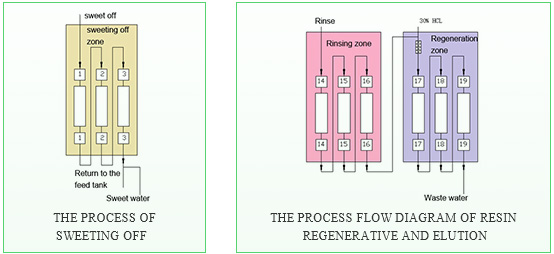

Taking off the sugar and regenerative process are carried out in series, so water and chemicals are used comprehensively.

3. Benefit to stable control of product quality

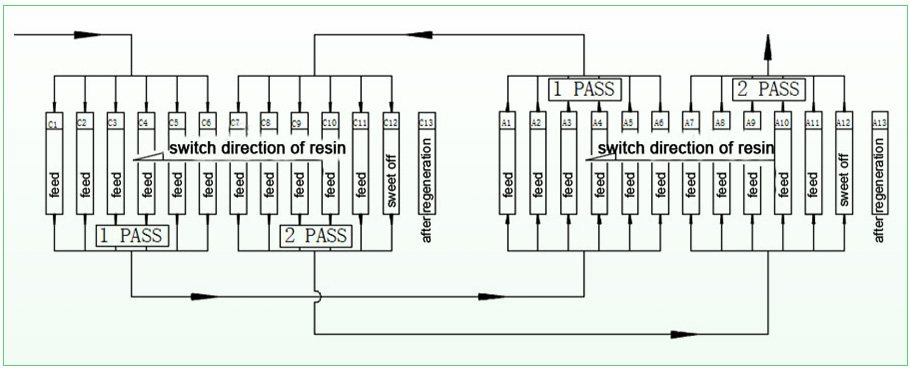

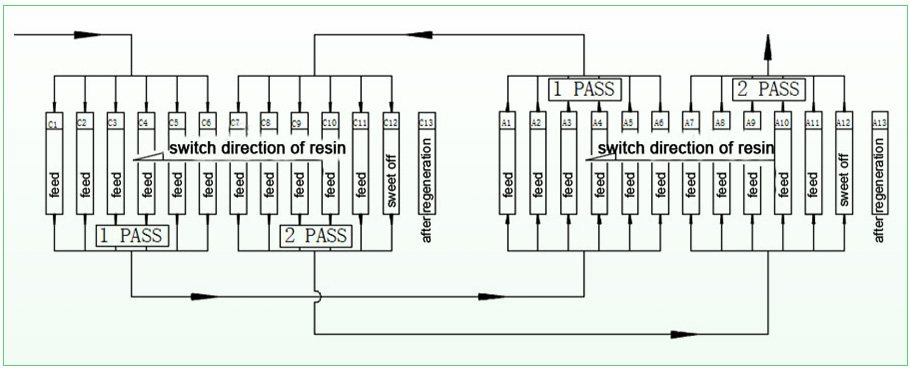

In the operation of fixed bed or other large beds systems, the column is switched, the product quality will fluctuate greatly (mainly in the concentration, conductivity, chroma, PH, etc.). Multi-unit system can treat materials cleanly in parallel. One small failure column is removed and the other small new column replaces that in time, which has nearly little effect on the whole system. The system running flow and resin switching mode are shown in Figure 5.

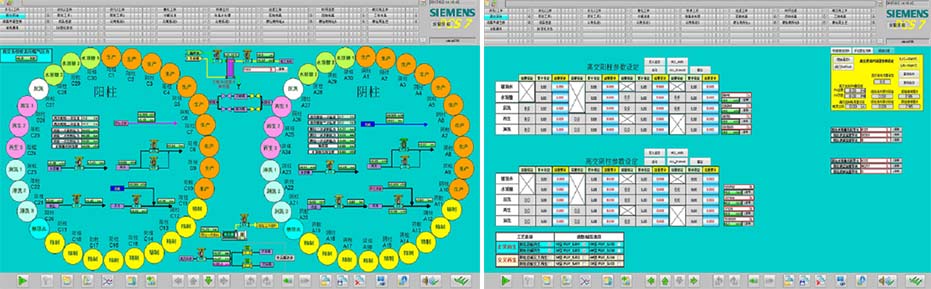

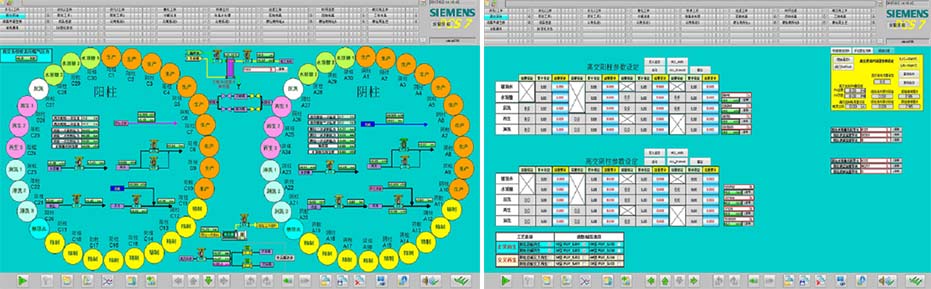

4. Fully automated operation reduces human factors

A fully automatic multi-unit ion exchange system uses the one-key start for easy operation. Acid, alkali, water, materials and the temperature can adjust themselves fully automatically. PH, conductivity and sewage discharge are all monitored on the line. It is enough for the workers to inspect the site.

5. Reliabilities of valves are the guarantee of system safety

Because the multi-unit continuous ion exchange system uses more than 500 valves and technological operation restricts one cycle with about 20 hours, they switch on or off less than 5,000 times for 10 years. This system adopts the imported pneumatic diaphragm valve from Switzerland. The service life of the valve is 250,000 times or 25 years, so the reliability of the system is greatly improved. Moreover, there are a few types of valves. there are generally two kinds of valves in the system and we only need to prepare two backup valves. the valve is connected by flare connection, which is very convenient to replace each other.

6. Our team has rich experience both in installation and commissioning on the site. In addition, our company has perfect service system after sale.

Compared with other equipment

Compared with other equipment

1. Compared with automatic full-bed ion exchange equipment

The biggest difference is multi units between multi-unit continuous ion exchange with array valves and full-bed ion exchange equipment. Because of it, water (30% off) and chemicals (60% off) are comprehensively utilized. The consumption of resin reduces 60% than before. Finally, one-time investment becomes lower but product quality is higher.

2. Compared with ISEP

Multi-unit continuous ion exchange equipment with array valves

-The multi-unit system uses a parallel method to purify the feed. one small failure column is removed and a small fresh column will move into the vacant place with each switch, which has little effect on the fluctuation of the whole system including flow and pressure. So it protect the whole system.

-The valve can be switched at any time (within a certain operate limits), which is very flexible in case of an emergency.

-Step switching and flow parameters can be set in coordination and the process operation is more refined (such as quick rinse and slow rinse).

-It is convenient to carry out subsequent expansion with the low investment and short cycle.

-The valve used is reliable, and the system is safe.

-ISEP equipment needs maintenance and management all the time.

Application

Application

1. Multi-unit continuous ion exchange equipment with array valves used in glucose, HFCS, maltose

2. Multi-unit continuous ion exchange equipment with array valves used in sorbitol, maltodextrin, dextrose monohydrate

3. Multi-unit continuous ion exchange equipment with array valves used in F55

4. Multi-unit continuous ion exchange equipment with array valves used in glucose and maltose

Multi-unit continuous ion exchange equipment with array valves is always used in the fields as follows.

Multi-unit continuous ion exchange equipment with array valves is always used in the fields as follows.

-Sugar industry

starch sugar, including glucose, dextrose monohydrate, fructose, crystalline fructose, F42, F55, maltose, dextrin, etc.; xylose.

-Chemical industry

Ethylene glycol and organic acids, the latter includes L-lactic acid, citric acid, VC, monosodium glutamate, and various amino acids, such as lysine, L-phenylalanine, leucine, methionine, etc.

-Food industry

Stevia sugar, sorbitol, and xylitol and sodium erythorbate, etc.

-Pharmaceutical industry

antibiotics, etc.

-Thermoelectric industry

water treatment, etc.